E-posformaatfout

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Exploring the Versatility of Surface RTD Temperature Sensor Applications

In the world of temperature measurement, precision is paramount. Surface RTD (Resistance Temperature Detector) temperature sensors are renowned for their accuracy and stability, making them a preferred choice for a wide array of applications. This blog post will delve into the functionality of surface RTD temperature sensors and explore the diverse range of RTD temperature sensor applications across various industries.

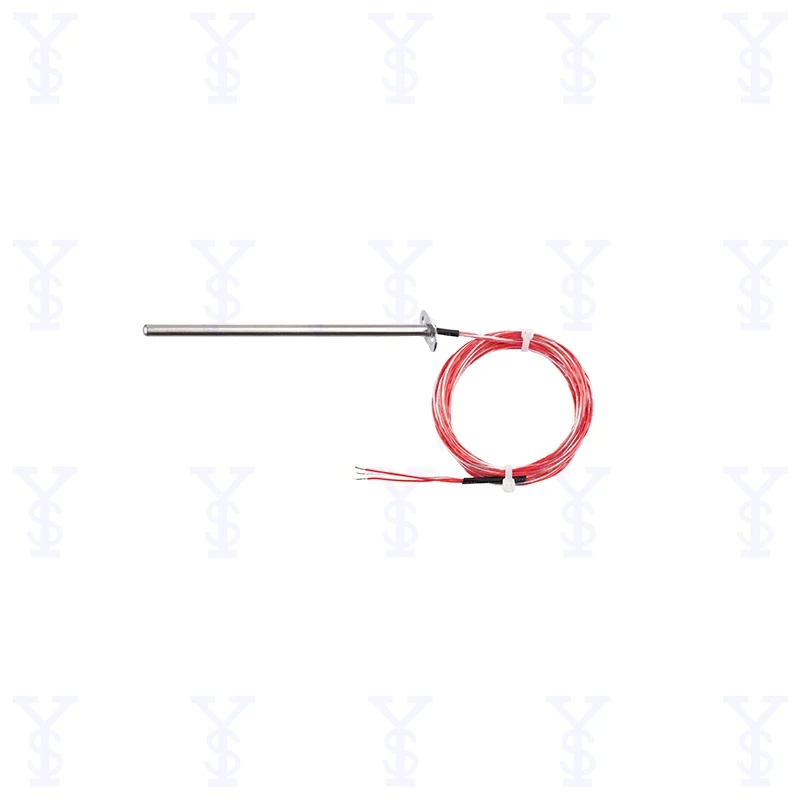

What is a Surface RTD Temperature Sensor?

A surface RTD temperature sensor is a type of temperature sensor that measures temperature by correlating the resistance of the RTD element with temperature. These sensors are designed to be mounted on surfaces to provide accurate temperature readings. Surface RTD sensors are typically constructed with a thin-film or wire-wound element, encapsulated within a protective housing, which is then attached to the surface whose temperature is being monitored.

Accuracy and Reliability of Surface RTD Temperature Sensors

Surface RTD temperature sensors are highly regarded for their precision and repeatability. They offer a wide temperature range, making them suitable for both low and high-temperature applications. The accuracy of RTD sensors is often within fractions of a degree, which is critical for processes where precise temperature control is necessary.

RTD Temperature Sensor Applications in Various Industries

The applications for surface RTD temperature sensors are vast and varied. Here are some of the key industries where these sensors are indispensable:

Manufacturing: In manufacturing, surface RTD temperature sensors are used to monitor machinery and processes. They ensure that equipment operates within safe temperature ranges and help in maintaining product quality.

Food and Beverage: The food and beverage industry relies on accurate temperature control for safety and quality. Surface RTD sensors are used in ovens, refrigerators, and food processing equipment to ensure products are cooked, stored, and processed at the correct temperatures.

Pharmaceuticals: In the pharmaceutical industry, precise temperature control is crucial for the production and storage of medications. Surface RTD sensors help maintain the integrity of drugs by monitoring and controlling temperatures throughout the manufacturing and storage processes.

Energy: In the energy sector, surface RTD temperature sensors are used in power generation plants to monitor the temperature of turbines, boilers, and other critical equipment. This helps in optimizing performance and preventing overheating.

Automotive: The automotive industry uses surface RTD sensors to measure the temperature of various components, such as engine blocks and brake systems, to improve efficiency and safety.

Aerospace: Aerospace applications require stringent temperature monitoring. Surface RTD sensors are used on aircraft surfaces and in various systems to ensure performance and safety at extreme temperatures.

Selecting the Right Surface RTD Temperature Sensor

When choosing a surface RTD temperature sensor for your application, consider factors such as temperature range, accuracy requirements, environmental conditions, and mounting options. It’s also important to select a sensor with the appropriate certifications for your industry, especially if you’re working in regulated sectors like food and beverage or pharmaceuticals.

Conclusion

Surface RTD temperature sensors are a critical component in many industries, providing the accuracy and reliability needed for precise temperature monitoring. The versatility of RTD temperature sensor applications highlights their importance in maintaining quality, efficiency, and safety across a broad spectrum of processes. Whether you’re in manufacturing, food production, or aerospace, understanding how to leverage the capabilities of surface RTD sensors can lead to significant improvements in your operations.